I faced a new challenge when assembling the first functional prototype of the UHK 80, our new split mechanical keyboard, about a year and a half ago. After years of hand-soldering PCBs, I needed a different approach.

The UHK 80 PCB contains wireless modules which only have pads beneath them, making iron soldering impossible. Additionally, the PCB has almost 500 SMD parts which are tedious to solder individually. I knew I had to up my game, and one of the most critical pieces of gear would be a pick and place machine.

Initially, I considered automatic pick and place machines, but as I only assemble a couple of PCBs per year, their price wasn’t justified for my needs. They also lacked 24mm feeders, and I realized the setup time would probably be too long for efficiently making individual prototypes.

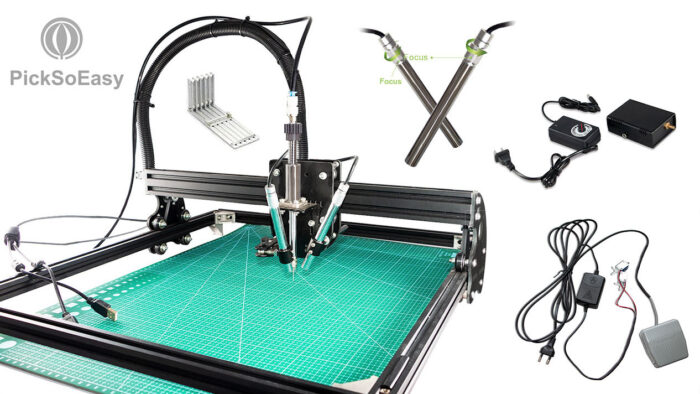

Then I discovered the PickSoEasy PSE-20-USB-2M, a machine with two smoothly moving axes, a rotatable vacuum pickup tool, and two USB cameras. For 567 euros, it seemed almost too good to be true. Slightly afraid but determined, I went ahead with the purchase.

When I got the package, the assembly instructions weren’t immediately clear to me, but Maurizio Romano, the creator of this machine, helped me quickly via email. He’s a great guy, and he truly cares about his product and customers.

The machine was already useful out of the box, but its pipe that conducted the vacuum tube and the USB cables of the two microscopes were in the way, covering my monitor. I modified it using a perforated metal strap and a drag chain, turning it into the manual pick and place machine of my dreams. While the PSE-20-USB-2M works great in its original form, this modification proved so beneficial that I believe Maurizio should consider incorporating it into the design.

The machine comes with essential features like a foot pedal for controlling suction, making component placement quick and precise. I’ve successfully used it with components down to 0603 size (1.6 x 0.8mm), though it may handle smaller sizes. The generous 31 x 25 cm work area accommodates most prototype PCB projects comfortably.

My current setup uses two monitors: a 4K display for the Interactive HTML BOM KiCad plugin on the right, and an HD monitor on the left showing the video streams from both microscopes, which is essential for placing fine-pitch components accurately.

And now, let’s see a short video of using the machine.

I’m sharing this experience because I believe the PSE-20-USB-2M offers exceptional value for hobbyists and small-scale PCB assemblers. This is my honest, unsponsored review.